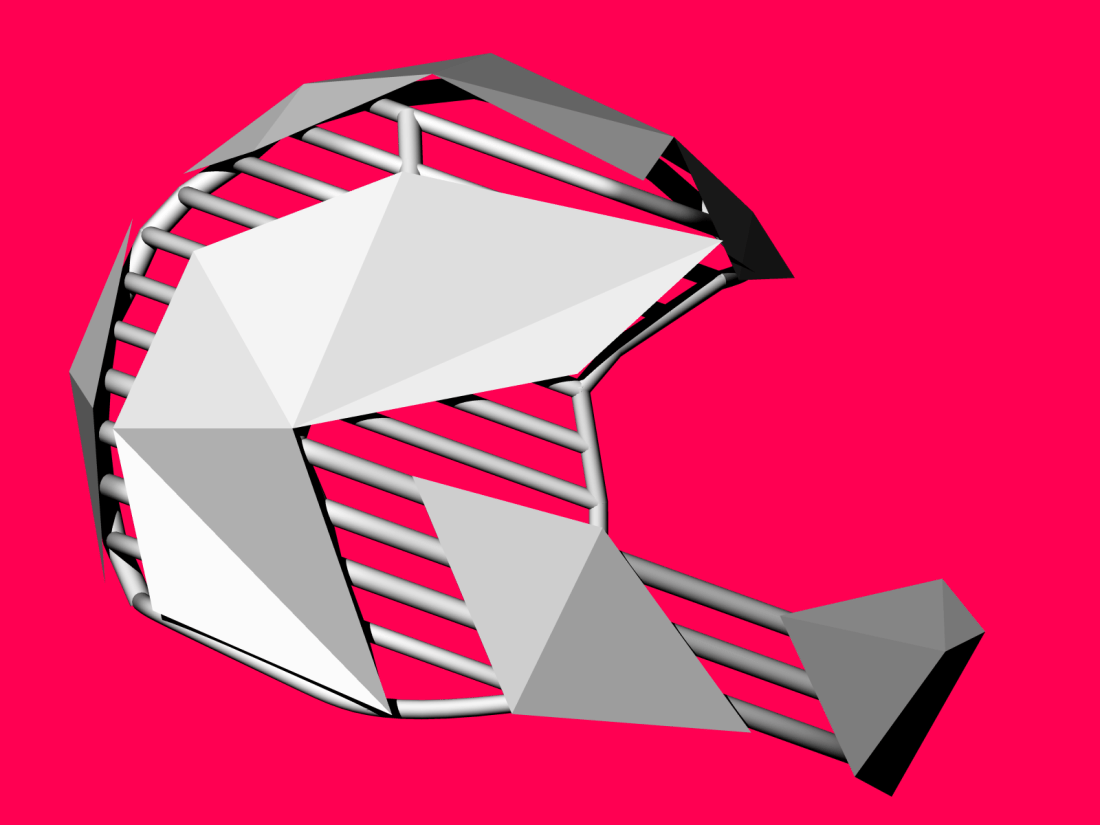

ABS plates correspond to Dietmar Otte’s study on helmet impact locations, covering over 75% of the most common impacts. A carbon tube skeleton works with the plating for greater impact distribution, especially important in the chin bar.

Traditional helmet design is a simple layering process of a hard outer shell, a thick polystyrene cap around the brain, and comfort padding for a snug fit. The foam layer is based not on the chance of impact, but on protecting the wearer from brain damage, and only works once. The outer shell can vary from cheap poly-carbonate, to common and adequate fiberglass, to racing-level carbon fiber.

Snell, an advanced helmet safety standard, drops a 3kg weight on the top and a 5kg weight on the chin bar, among other tests. These are tests of rigidity and favor carbon fiber, yet are inadequate per Otte’s results. This design is a response to the gaps in Snell’s testing.